Test Equipment

Case Study #1

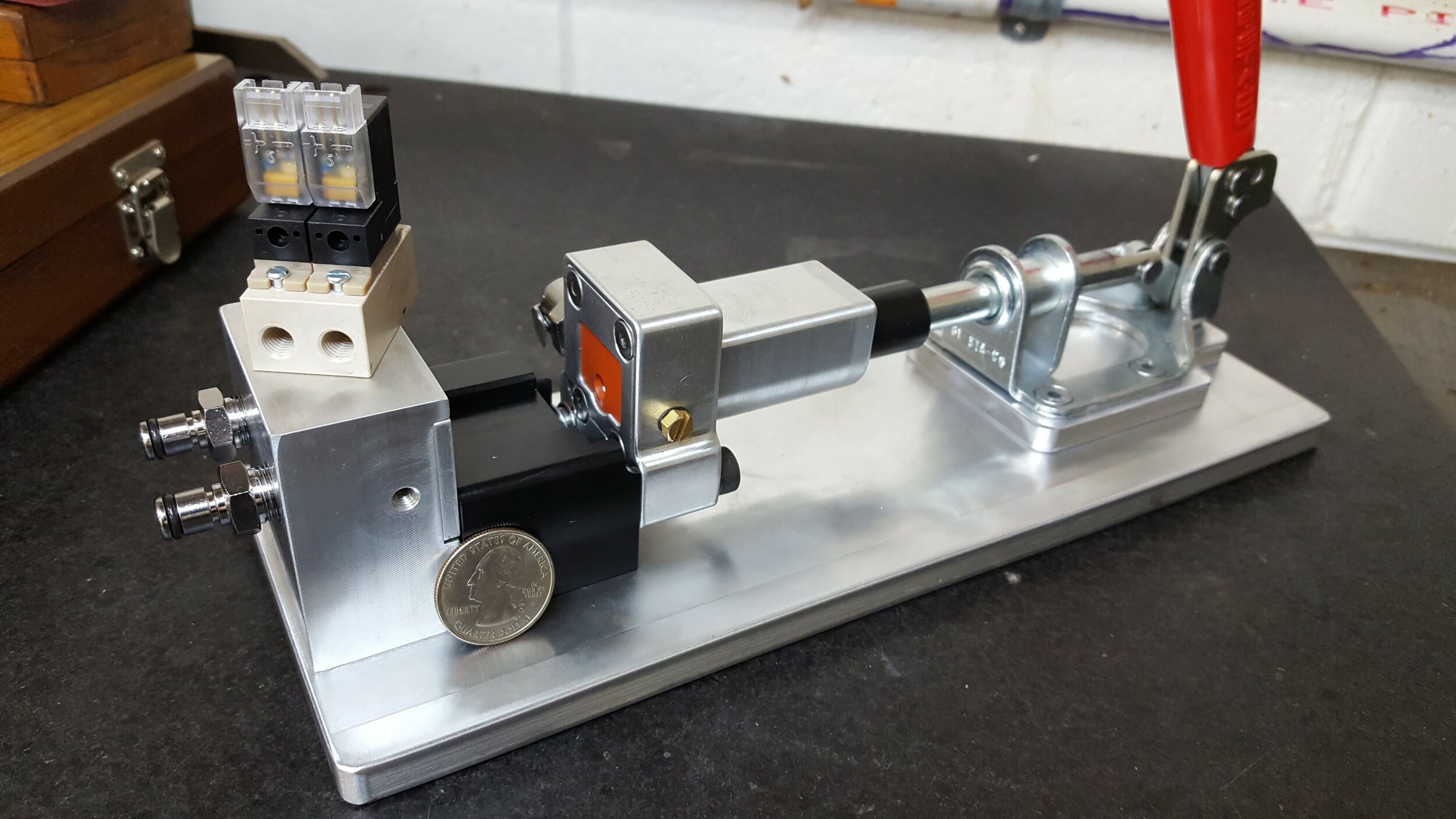

Medical Valve Test Fixture

MWW1 was contracted to design, fabricate a manually operated test fixture for a medical valve manufacturer.

➢ Customer required 100% inspection of valve assemblies & required a manually operated test fixture to standardize the test process, without threading mating components into the valve being tested

➢ Customer timing was “ASAP

• MWW1 went from a “napkin” sketch w/ customer

to providing a working test assembly in under

2 weeks.

• Included along with functioning test fixture, full

CAD & drawings of the components & assemblies

so that additional units could be created if necessary.

Case Study #2

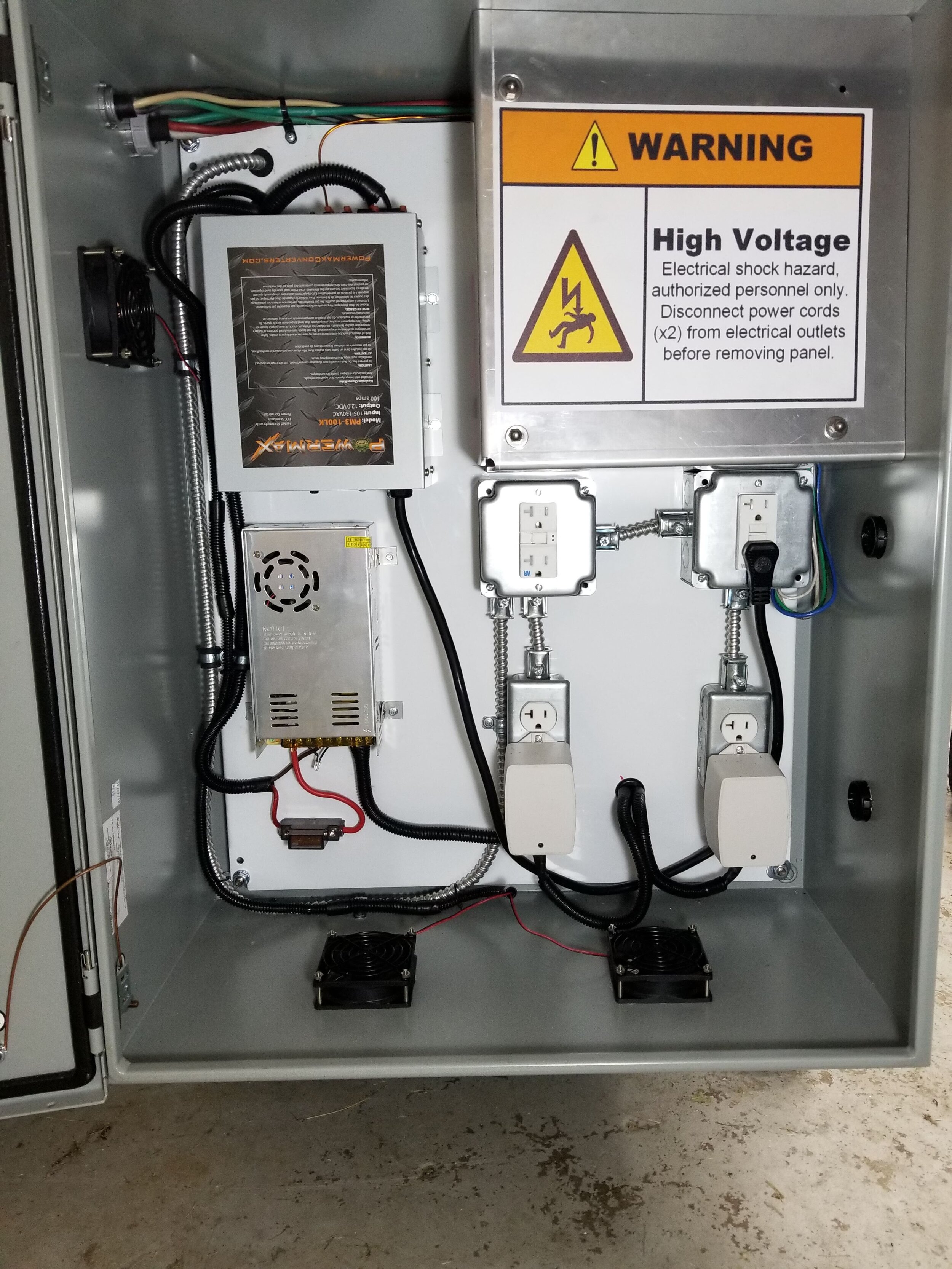

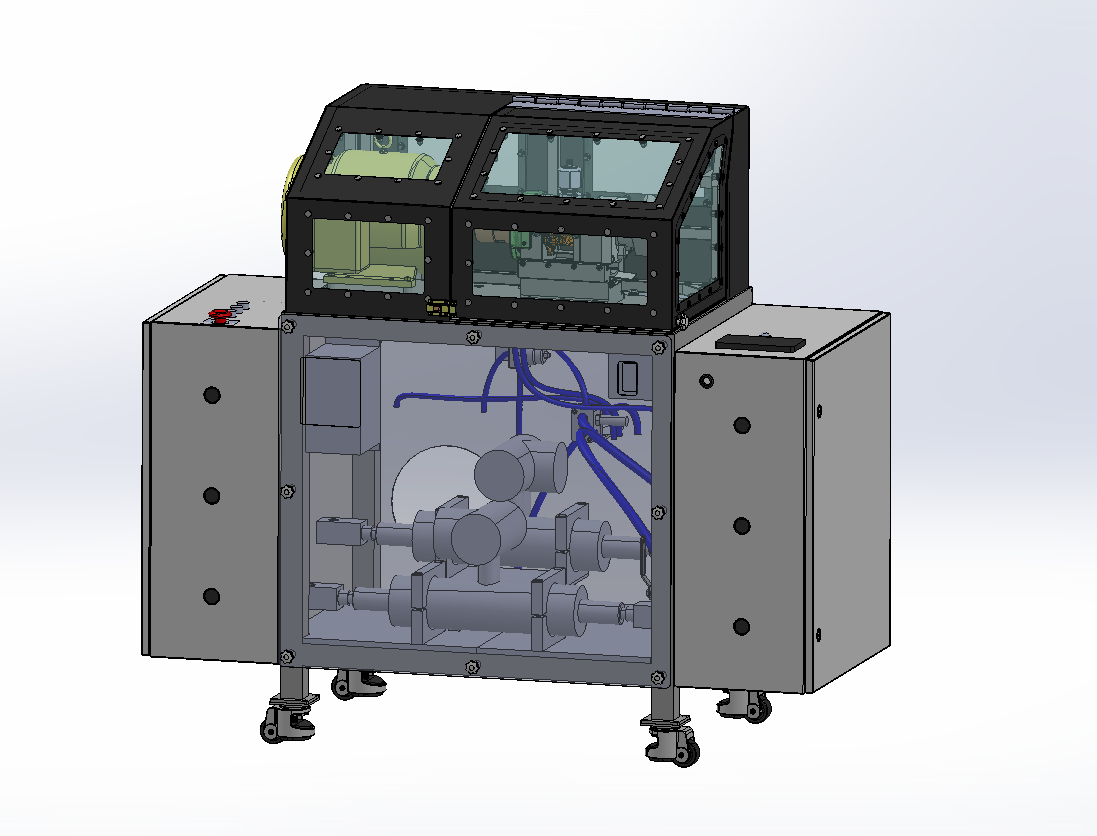

Fuel Pump Test Stand

MWW1 was contracted to design & fabricate an “End of Line” Test Stand, for our

automotive fuel systems customer

➢ Customer required 100% inspection of all fuel pumps

➢ Customer wanted to be responsible for controls & calibration

• MWW1 led the mechanical development of the EOL test stand, working closely with

the customer to develop the stand specifications.

• MWW1 design, machined & fabricated the test stand, including high & low voltage

electric circuitry, and hydraulic circuits.

• Included along with functioning test stand, full CAD &

drawings of the components & assemblies so that additional

units could be created if necessary.